NG 900/9-3 Alternator Replacement

Contents

Overview

The Bosch alternator used in the NG900 is supposed to last 100-150k miles, but driving conditions can shorten its life just like any other part.

Replacement

Tools

Steps

The alternator is located on the back side of the engine. The alternator pulley is the third from the top, below the upper idler pulley and the tensioner. The Haynes manual for RHD cars recommends removing the alternator "via the right-hand wheel arch" (fender), but this turns out to be impossible on LHD cars. I removed mine straight up between the engine and the strut tower brace.

Airbox and Serpentine Belt

See Fig. 1 The following were removed first to get good access to the tensioner and upper alternator bracket:

- Air filter housing

- Serpentine belt

- Upper idler pulley

Crankshaft Access Panel

See Fig. 2 The lower mounting bracket and bolt are to the left of the crankshaft pulley.

- Car was jacked up in front and supported on stands

- Front passenger wheel removed

- Crankshaft access panel removed

Strut Tower Area

See Fig. 3 To make room to pull the alternator straight up, the following was disconnected and moved aside

- Cruise control box wire connector (not cable)

- Purge valve inlet hose

- IAC valve inlet hose

- MAP sensor cable (not the vacuum hose)

Components

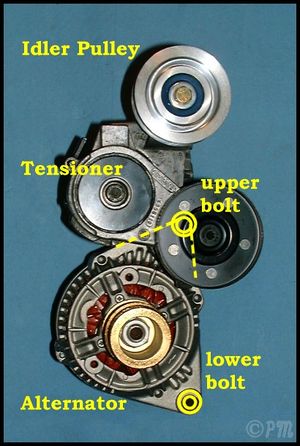

See Fig. 4 The idler pulley, belt tensioner, and upper alternator bolt attach to the same bracket at the top of the engine.

The tensioner is attached by a long allen-type bolt in the center of the spring arm, shown in the locked position.

The upper alternator bolt is hidden behind the tensioner arm. The lower bolt would be attached to a second bracket in the car which also goes around the left drive shaft.

Tensioner and alternator bolts are identical. Liquid Wrench or PB Blaster must be used on both ends of the bolts to get them loose safely.